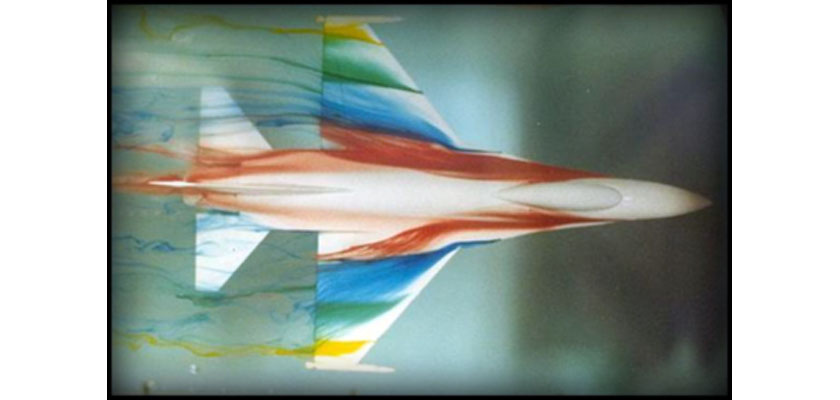

AEROLAB Water Tunnels are designed to offer sufficient size, precision and Reynolds number capability for research.

Yet they are also rugged and simple enough for educational use.

Performance Specifications

Top Speed:

- nominally – 30 ft/sec (9.1 m/s)

- demonstrated – 60 ft/sec (18.3 m/s)

Detailed Description

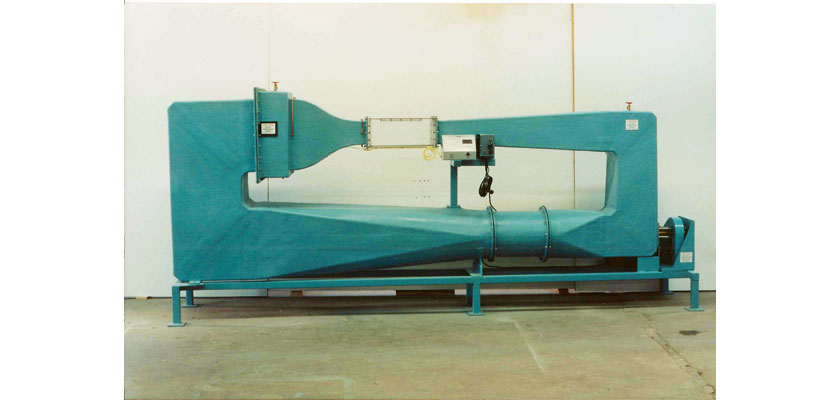

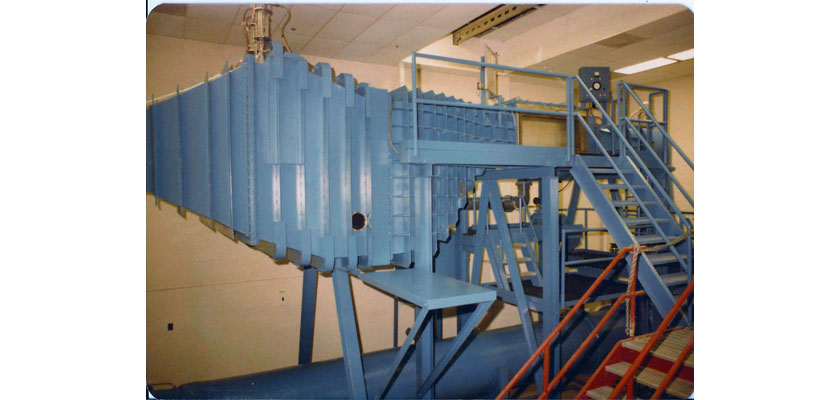

- Construction – The entire shell and all parts exposed to water are fabricated of stainless steel, brass or fiberglass to maintain the circulating waters’ crystal clarity.

- Contraction – Contraction ratio (inlet-to-outlet area ratio) is a major driver in the overall size and complexity of a water tunnel. Power requirements, accordingly, follow. AEROLAB uses either a fifth or a ninth-order polynomial to define a smooth transition between the settling chamber (contraction inlet) and the test section entrance.

- Honeycomb Flow Straightener – High quality, high-aspect-ratio stainless steel or plastic honeycomb flow straightener is installed in all AEROLAB water tunnels.

- Static Pressure “Rings” – Static pressure “rings” are fitted in the widest section of the contraction and at the entrance of the test section. Both rings consist of at least four pressure taps (one centered on each wall) sharing a common manifold. The pressure measured within the “rings” is used to calculate flow speed without the need of an invasive probe or sensor. Depending upon tunnel size, additional taps may be employed.

- Test Section – Depending upon size, speed and customer preference, AEROLAB Water Tunnel test sections can be made either entirely of clear Acrylic or framed of stainless steel with removable Acrylic windows.

- Diffusers – To prevent airflow “separation” in the diffusers, and hence diffuser-related effects in the test section, AEROLAB restricts included diffuser divergence angles to 5º. Diffusing corners are not used.

- Turning Vanes – Similar to Closed-circuit wind tunnels, Water tunnel circuits include four 90° “corners” (turns) to return flow to the test section. In order to do this smoothly and efficiently, each corner must employ turning vanes. AEROLAB installs engineered turning vanes in each corner.

- Pump – AEROLAB pumps are designed for uniform discharge velocity. This uniformity is seen as excellent test section flow quality and helps to reduce cavitation when the pump is working at low pressure. Test section flow speed is controlled by an externally mounted, variable-speed motor.

- Modular Design – For ease of shipment and installation, tunnel sections are flanged.

- Steel Support Structure – Stainless steel tubular legs and cross members are used to support the tunnel.

Type

- Specialty Tunnels/Equipment

Performance Specifications

Top Speed:

- nominally - 30 ft/sec (9.1 m/s)

- demonstrated - 60 ft/sec (18.3 m/s)